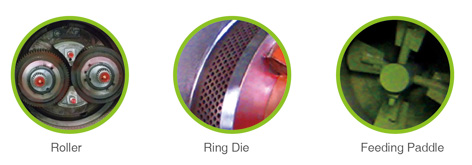

Ring Die Pellet Mills are widely used to a large scale wood pellets production line for light industrial and commercial purposes. They are not as widespread as those with flat dies due to the increased complexity of machines and higher cost. As the die's name suggests, the ring die has a wide cylindrical shape and it is mounted vertically. A surge bin is used to feed biomass materials through a variable speed conditioner before being distributed via the pelleting machine door. A screw auger is useful at this last step of putting the materials in the pellets machine chamber.

Ring Die Pellet Mills and Details

Advantages of Ring Die Pellet Mills

There are two main distinct points of ring die: it generates less wear and tear, since both the inner and outer edges of the roller traverse the same distance; and it is also more energy efficient than a flat die pellet mill design. Roller slip during the pelleting process brings extra friction, but this extra friction is an accelerating element in the production of quality wood pellets due to the additional heat.

Details of Ring Die Pellet Machine

Main Technical Parameters of Ring Die Pellet Mills

| Type | Capacity | Power | Ring Die Capacity | Pellet Specifications |

| KMPM42 | 1-1.5t/h | 95kw | 800-1000t | 6mm/8mm/10mm/12mm/14mm |

| KMPM508 | 1.5-2t/h | 115kw | 1000-1200t | 6mm/8mm/10mm/12mm/14mm |

| Type | Forming rate | Ability to operate | Noise | Dimensions |

| KMPM42 | ≧95% | ≧20h | ≦88dB[A] | 3300*1200*3943(mm) |

| KMPM508 | ≧95% | ≧20h | ≦90dB[A] | 3450*1470*4445(mm) |

| Type | Weight | Pellet energy consumption | Main motor speed |

| KMPM42 | ≈3t | ≈85° | 1000r/min |

| KMPM508 | ≈4.5t | ≈80° | 1000r/min |

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!

Your privacy is important to us,we are committed to marking sure your privacy is confidential.